With adequate measuring tools, such as industrial needle manometer 0-600Pa and pressostat, you can easily control the clogging of the placed filters. AIRWATEC takes care of the maintenance and replacement of used filters.

Thanks to its expertise and experience in the advanced air filtration technics, Airwatec performs full audits with in-depth technical and commercial analysis to offer optimal solutions for the customers.

- Assessment of air movements

- Research for the optimal filtration system by integrating all the operating parameters such as cost, energy, labor, maintenance, …

- Quotation on 3D CAD plans.

- Technical feasibility and economic viability analysis in accordance with your production and maintenance units

- Manufacturing in Belgium of industrial air filtration boxes for flow rates from 100 m3/h to 1.000.000 m3/h and more

- Monitoring of the whole installations of filtration or dedusting of a site or several sites

- Performance monitoring: air flow, air speed, air quality, pressure drop, heat balance

- Maintenance/replacement service of installed filters by qualified staff (with VCA certification for petrochemicals) including a full offer for the optimization of your installations in terms of longevity, price, energy savings and operating profitability.

Our long experience in engineering projects in the fields of power generation, petrol and gas industry, chemicals, paper factories, food and beverage industry and industrial painting can be seen in many projects carried out mainly in Belgium, Luxembourg and in northern France.

Our references include air filtration systems for gas turbines and compressors, ventilation systems for control rooms or production factories in the energy, steel, cement, automobile, petrochemical, technical gas, agro-food sectors…

We will be pleased to show you some of our specific project references during a personal meeting.

-

Manufacture of made to measure boxes.

The air filter boxes are designed in such a way that they are an integral part of the manufacturing process. They ventilate the passivation booths and vacuum all types of dust, e.g. enamel, silicon carbide fumes, etc. -

Placement of reject chimney

The filtration of the fumes from a furnace via the mounting and placement of spiral galvanized steel sheaths of suitable diameter, with a waterproofed roof passage and a vertical discharge cap, are part of the many achievements of AIRWATEC's team of industrial engineers. -

Fine filtration in front of gas compressors

Tiered filtration with filters of different capacities and classes to capture the finest dust. Ease of mounting and dismounting of filters. Durable gaskets ensure the waterproofing. -

Chemical filtration in the paper industry

by stainless steel hoods and flexible sheaths of connection of the steamers to the nozzles and evacuation with ventilator under roof. A vat is used to collect the greasy drains. -

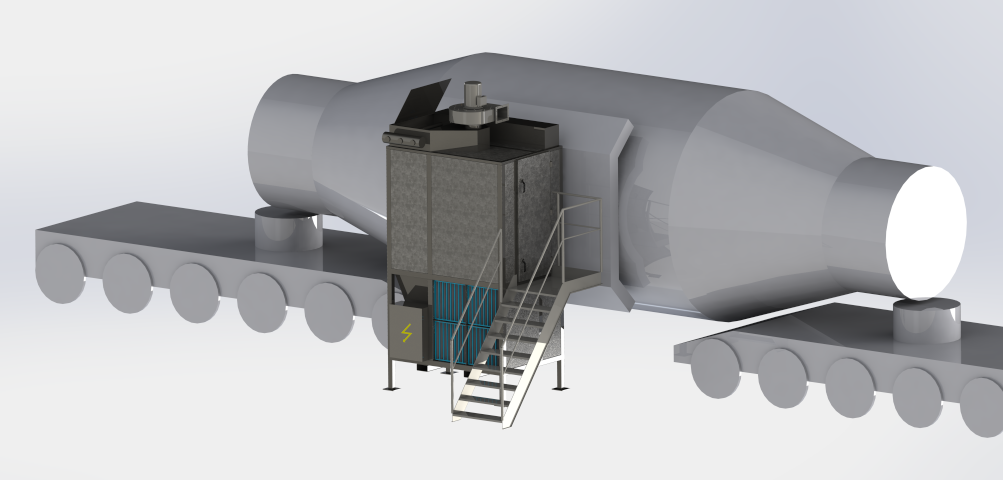

Air filtration in front of a turbo machine

via a vacuum canopy with a reinforced steel bird screen and a square profile box equipped with steel sheets and fixing brackets. -

Hot air recovery on compressors

is a steel duct system with reduction to connect to the axial recovery fan with overpressure valve and a register equipped with a servomotor. -

Filtration for sterilization

delivered with a self-regulating valve and a ventilation group with a M6 filter, a heating battery, a fan with pressostat and a steam humidifier with stainless steel injection ramp. -

Filtration by ventilation

to evacuate the cumulated losses with a flow modulated according to the needs. The air entry is composed of silencers placed between the doors of the local and the extraction is placed on the roof. -

Filtration before the electrical cupboards.

Use of filter frames for framing with galvanized steel runners fixed to the cupboard doors. -

Fine dust filtration - dusting

Our dust collectors, ducting networks and collection systems are tailor-made to best suit your dust emissions, aiming to improve safety at work, protect the environment and your technical systems. -

Dusting

Shot blasting, sand blasting, powdering, ... all industrial activities in surface treatment that give off dust that is harmful to employees and the environment as well as to the work tool. The Engineering department has tailor-made dust removal solutions.