The positive effect of the air filtration on gas turbine performance degradation

The degradation of the gas turbine power and compressor efficiency over time is strongly influenced by the amount and composition of particles that enter into the compressor. This amount is on one hand affected by the chosen air filtration level, and on the other hand by the size distribution, the weight and the chemical composition of the particles in the ambient air.

The introduction of the new global standard ISO 16890 has brought a different approach to assessing the filtration efficiency as a foundation for filters classification: filters efficiencies will be determined according to the separation efficiencies of the PM1, PM2.5 and PM10 particle fractions.

Our engineering office will tell you more about the correlation between the output power, respectively the efficiency degradation of the compressor, the performance of the installed air filters and the concentration and mass distribution of dust particles at the gas turbine location.

Discover our selection of multi-stages filtration systems

-

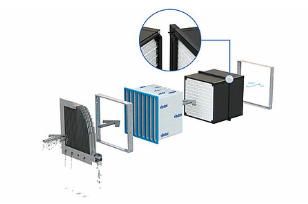

Ideal for maximum purity at the EPA level: 3 stages with bag filters, MaxiPleat and eMaxx cassette filters.

Ideal for maximum purity at the EPA level: 3 stages with bag filters, MaxiPleat and eMaxx cassette filters. -

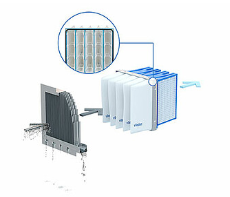

Ideal for preventing water infiltration: hydroMaxx pocket filter firmly fixed on the eMaxx cassette filter.

Ideal for preventing water infiltration: hydroMaxx pocket filter firmly fixed on the eMaxx cassette filter. -

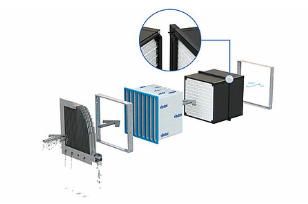

Ideal for tight spaces: the MaxiPleat modular filter system as a 2-in-1 solution.

Ideal for tight spaces: the MaxiPleat modular filter system as a 2-in-1 solution. -

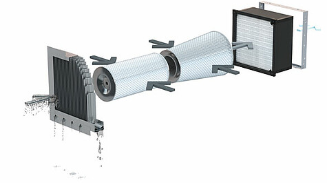

Ideal for cleanable systems with safety filter stage: pulse jet filter cartridges (conical/cylindrical) with MaxiPleat cassette filter.

Ideal for cleanable systems with safety filter stage: pulse jet filter cartridges (conical/cylindrical) with MaxiPleat cassette filter.